HVAC anti-vibration

HVAC (Heating, Ventilation, and Air Conditioning) systems are essential for maintaining indoor comfort, but they can also create vibration problems that negatively affect both the system itself and the surrounding environment. These vibrations can be transmitted through building structures, leading to unwanted noise, reduced equipment lifespan, and even damage to surrounding infrastructure. Here’s a closer look at the key issues and how they can be mitigated. We’ll analyse some of the common problems to HVAC systems caused by affects of vibration as well as Isotop vibration isolation solutions to rectify these issues.

Resources Features and Benefits Anti-Vibration Importance HVAC Anti-Vibration Polyurethane Vibration Dampeners

Vibration problems commonly found in HVAC systems

Equipment-Induced Vibration

HVAC equipment like compressors, fans, motors, pumps, and chillers often have moving parts that create vibrations during operation. Over time, these vibrations can:

- Damage internal components of the HVAC system.

- Lead to misalignment of rotating parts, causing further inefficiency.

- Increase wear and tear, reducing the overall lifespan of the equipment.

Structure-Borne Noise

Vibrations from HVAC systems are easily transmitted through the building structure, especially if they are installed on rigid surfaces like concrete floors or steel beams. These vibrations travel through walls, floors, and ceilings, resulting in:

- Noise pollution, which can be disruptive in offices, residential buildings, hospitals, and other sensitive environments.

- Resonance within the structure, where the vibration amplifies at certain frequencies, making the noise worse.

Low-Frequency Vibration Issues

HVAC systems, especially large ones like rooftop units or industrial chillers, tend to generate low-frequency vibrations. These vibrations travel farther and are harder to isolate, causing greater disruption in buildings over long distances. Low-frequency vibration is particularly challenging because:

- It can be transmitted over long distances through rigid building structures.

- Traditional damping materials may not be effective at isolating low-frequency vibrations.

Imbalance and Misalignment

Imbalance in rotating components (such as fans and motors) or misalignment in pumps and compressors can significantly increase vibration levels. These issues often arise from:

- Wear and tear over time.

- Poor installation or inadequate maintenance.

- Manufacturing defects.

Impact on Building Integrity

Persistent vibration from HVAC systems can impact the structural integrity of a building. Over time, repeated exposure to vibrations can lead to:

- Cracking in walls and ceilings.

- Loose fittings and fixtures.

- Compromised insulation or sealing, reducing building energy efficiency.

Solutions to solve your HVAC vibration problems

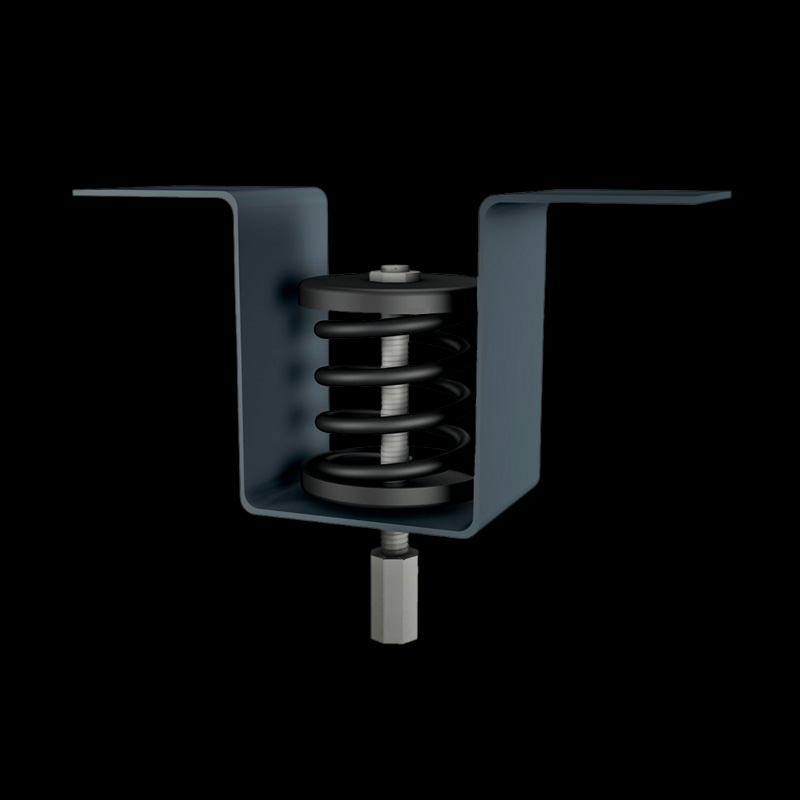

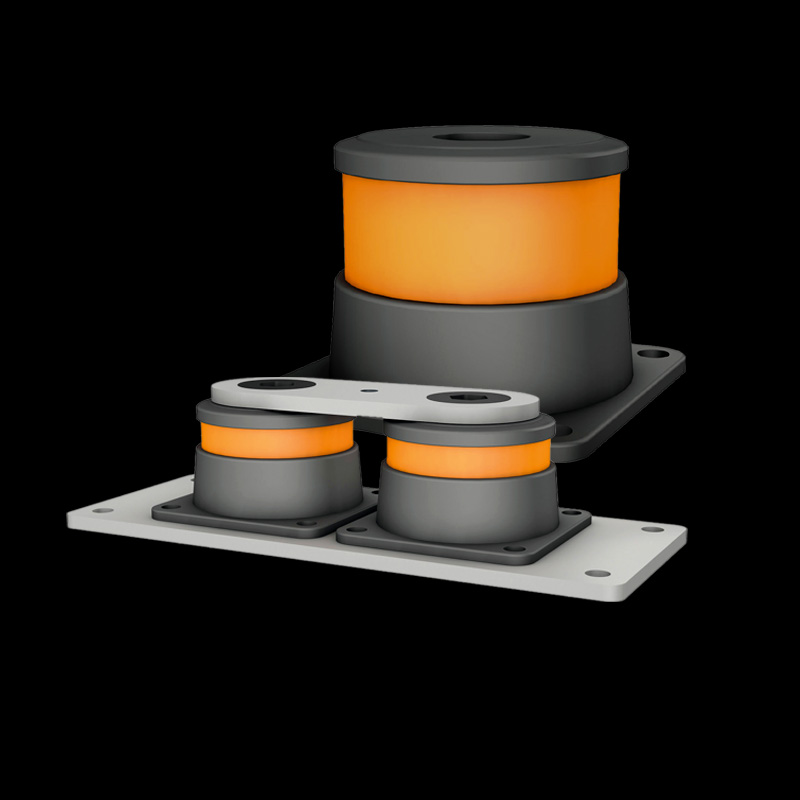

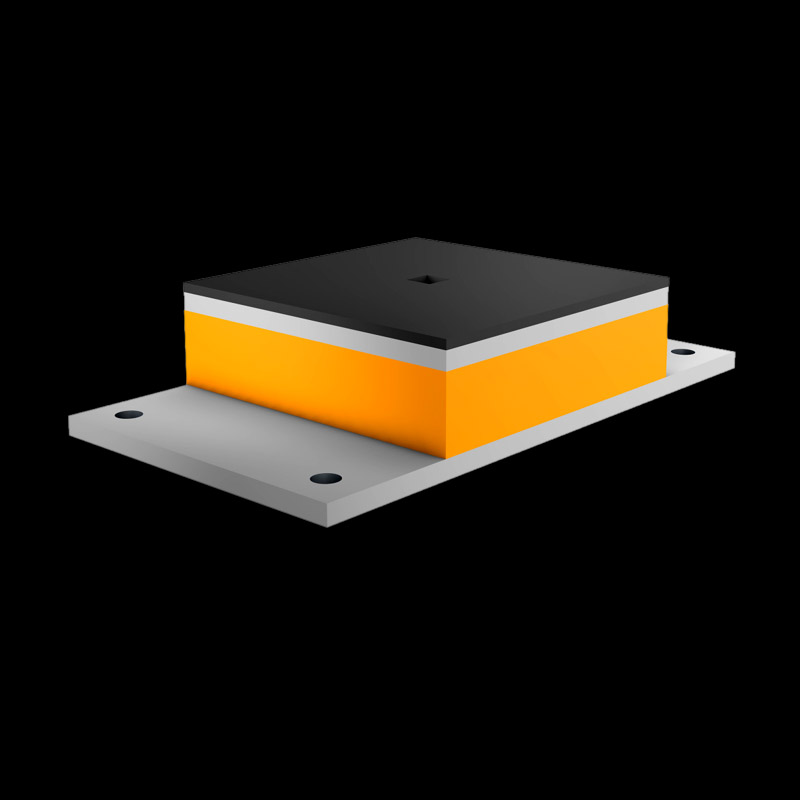

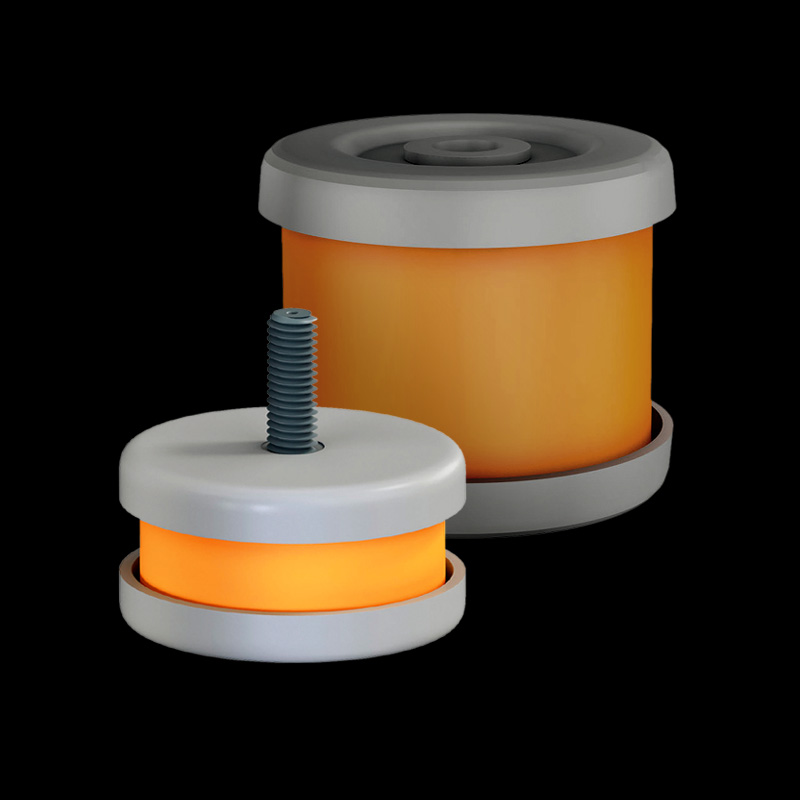

Vibration Isolation Systems

Isotop Products from Getzner are excellent examples of vibration isolation systems for HVAC applications. They use a combination of elastomeric materials and metal springs to isolate the equipment from the building structure.

Flexible connections: Using flexible piping and ductwork connections (instead of rigid ones) can prevent vibrations from traveling through hard materials.

Proper Installation

The correct installation of HVAC equipment is crucial for minimizing vibration issues.

Ensuring that equipment is properly aligned and balanced from the start can prevent many vibration problems from occurring later on.

Maintenance and Monitoring

Regular maintenance of HVAC systems is essential to catch vibration problems early. Key maintenance practices include:

Balancing rotating components (like fans and motors) to ensure they operate smoothly. Checking for misalignment in pumps and compressors and correcting them as needed. Replacing worn-out components that may cause excessive vibration.

Benefits of vibration control in HVAC systems

Reduced Noise

Proper vibration isolation will significantly reduce the amount of structure-borne noise transmitted into the building, improving comfort for occupants.

Increased Equipment Life

By reducing wear and tear caused by vibrations, HVAC equipment will last longer and require less maintenance.

Enhanced Energy Efficiency

Vibrations can make HVAC systems work harder, reducing their efficiency. Proper vibration control helps systems run more smoothly and efficiently.

Prevent Structural Damage

Controlling vibrations prevents long-term damage to the building structure, reducing the need for costly repairs.

Conclusion, HVAC systems often generate unwanted vibrations that can lead to noise, equipment damage, and even structural issues in buildings. Addressing these problems with proper vibration isolation techniques, such as using Isotop products, anti-vibration mounts, and regular maintenance, can greatly improve the system’s performance and longevity. Solving vibration problems not only protects the HVAC system itself but also ensures a quieter, more comfortable environment for building occupants.