Anti-vibration importance

Machine anti-vibration is crucial for a variety of reasons, including enhancing equipment performance, longevity, safety, and operational efficiency. Uncontrolled vibrations can lead to mechanical failures, increased wear, noise pollution, and even safety hazards. In short, minimising machine vibration is essential for ensuring the longevity, efficiency, safety, and reliability of equipment. Listed below are some of the key reasons why minimising machine vibration and its impact on your equipment is so important.

Resources Features and Benefits Anti-Vibration Importance HVAC Anti-Vibration Polyurethane Vibration Dampeners

Key reasons why machine anti-vibration is so important

Improved Equipment Lifespan

Excessive vibration causes wear and tear on mechanical components such as bearings, gears, shafts, and fasteners. This leads to fatigue and failure of critical parts, shortening the overall lifespan of the machine.

Components like rotating parts (motors, pumps, fans) experience more stress under vibration, which can lead to misalignment and imbalance that further accelerates the degradation of the machine.

Anti-Vibration Enhances Operational Efficiency

Machines that vibrate excessively are less efficient because they require more energy to operate smoothly. The energy used to counteract vibration is wasted, making the system less productive and increasing operational costs.

By reducing vibration, you ensure the machine runs at its optimal capacity, conserving energy and improving productivity.

Reduced Maintenance Costs

Machines that vibrate frequently require more frequent maintenance to fix issues like misaligned components, loosened fasteners, and damaged bearings.

Reducing vibration lowers the need for constant repairs, thereby reducing downtime and lowering maintenance costs.

Improved Product Quality

Machines involved in manufacturing processes, particularly precision equipment like CNC machines, printing presses, or textile machines, must maintain strict tolerances. Vibration can cause deviations in these tolerances, leading to defective products and inconsistent quality.

Vibration-free machines help produce products with greater accuracy and consistency, resulting in higher quality and fewer rejected items.

Enhanced Safety

Excessive machine vibration can create hazardous conditions for operators and workers in industrial environments. Vibrating components can loosen fasteners or even cause machinery to fall out of alignment, leading to mechanical failures that can cause injuries.

Prolonged exposure to vibration can also result in vibration-related health issues, such as hand-arm vibration syndrome (HAVS) or whole-body vibration issues, affecting workers’ well-being. Reducing vibration helps ensure a safer working environment and minimizes the risk of equipment malfunctions or accidents.

Noise Reduction

Vibration often results in structure-borne noise, where vibrations are transmitted through building structures or surrounding equipment, causing loud and disruptive noise.

Reducing machine vibration leads to less acoustic noise, creating a more comfortable working environment and minimizing noise pollution in areas like offices, hospitals, or residential buildings.

Prevention of Structural Damage

Vibrations from heavy machinery can be transmitted through floors, walls, and other structures in the building, causing long-term damage such as cracking or weakening of the structure.

Over time, vibrations can cause foundational issues, leading to expensive repairs or even structural failure. Proper vibration control prevents this from happening.

Increased Reliability and Predictability

Machines that vibrate excessively are more likely to experience unexpected breakdowns, which can cause significant disruptions in production processes.

Reducing vibration makes machinery more predictable and reliable, allowing for better planning and fewer unexpected downtimes, which is critical for high-output operations.

Protection of Nearby Equipment

Vibrations from one machine can affect adjacent machinery or sensitive equipment, especially in industrial settings where multiple machines are running simultaneously.

For example, vibrations from heavy equipment can disturb delicate instruments in laboratories or precision machinery in manufacturing, reducing the accuracy and performance of nearby devices.

Compliance with Regulations

Many industries, especially in manufacturing, require machines to meet certain standards in terms of vibration levels. Excessive vibration can lead to non-compliance with safety or operational standards set by regulatory bodies.

Reducing vibration helps companies adhere to industry-specific guidelines, avoiding fines or penalties.

Energy Conservation

Machines vibrating out of sync use more energy to complete the same task.

Reducing vibration minimizes this energy wastage, contributing to better energy efficiency and lowering the operational costs associated with running equipment.

Environmental Impact

In some cases, reducing vibration can lead to a quieter and more environmentally friendly operation.

Excessive noise and vibration pollution from machinery can affect nearby ecosystems and communities. By controlling vibration, companies can reduce their environmental footprint.

Further reading

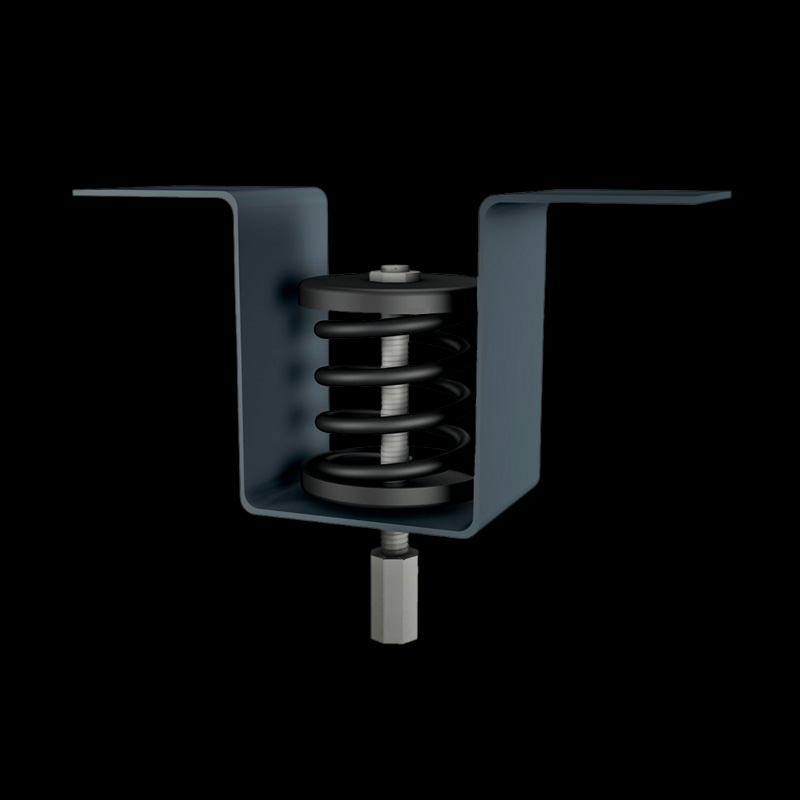

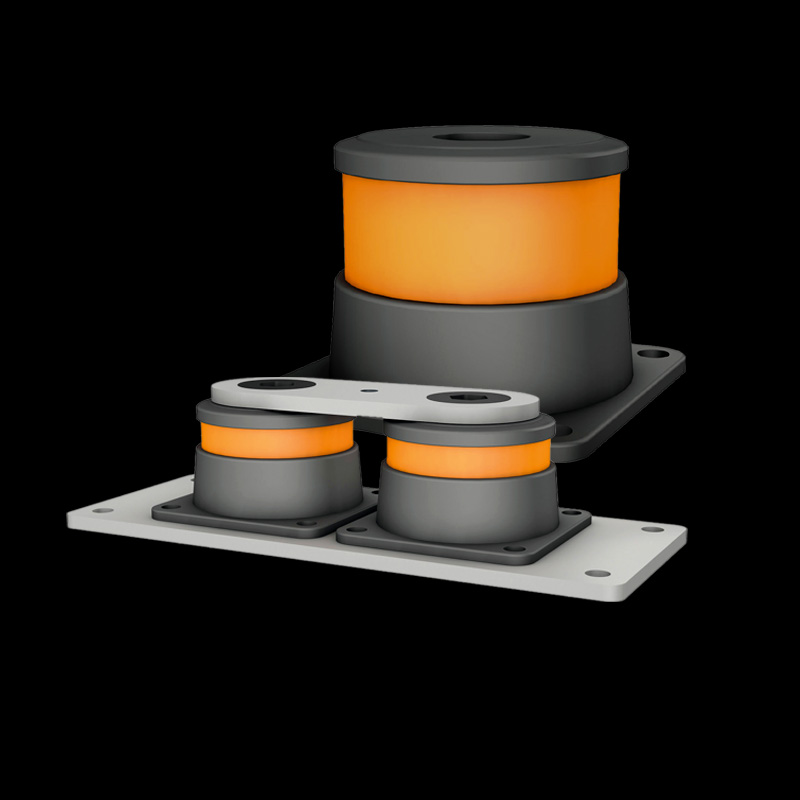

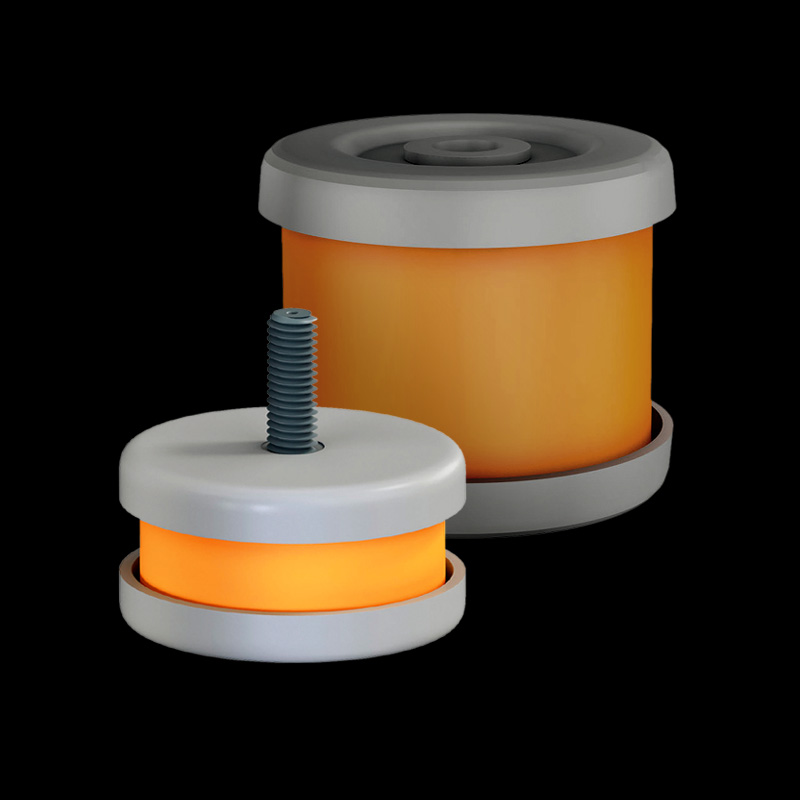

Isotop Features and Benefits

Isotop products from Getzner Werkstoffe are specifically designed to stop or significantly reduce machine vibration, making them ideal for a wide range of industrial applications.

HVAC Anti-Vibration

HVAC systems are essential for maintaining indoor comfort, but they can also create vibration problems that negatively affect both the system itself and the surrounding environment.

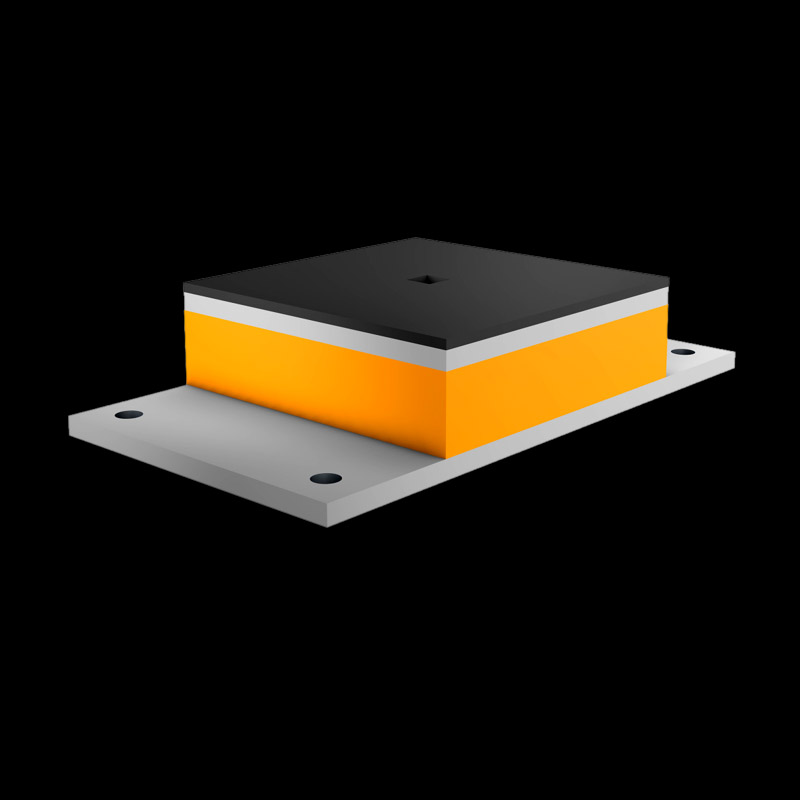

Polyurethane V Rubber

Polyurethane (Sylomer, Sylodyn, Sylodamp and Isotop) is often considered a better vibration damper than rubber in most applications due to its unique combination of mechanical properties.

In conclusion, machine anti-vibration is essential for ensuring the longevity, efficiency, safety, and reliability of equipment. In addition to improving product quality and reducing maintenance costs, controlling vibration helps to prevent structural damage, protect surrounding equipment, and create a safer, quieter working environment. Investing in proper vibration isolation techniques is a proactive measure that pays o in reduced downtime, enhanced productivity, and overall operational efficiency.