Polyurethane V Rubber

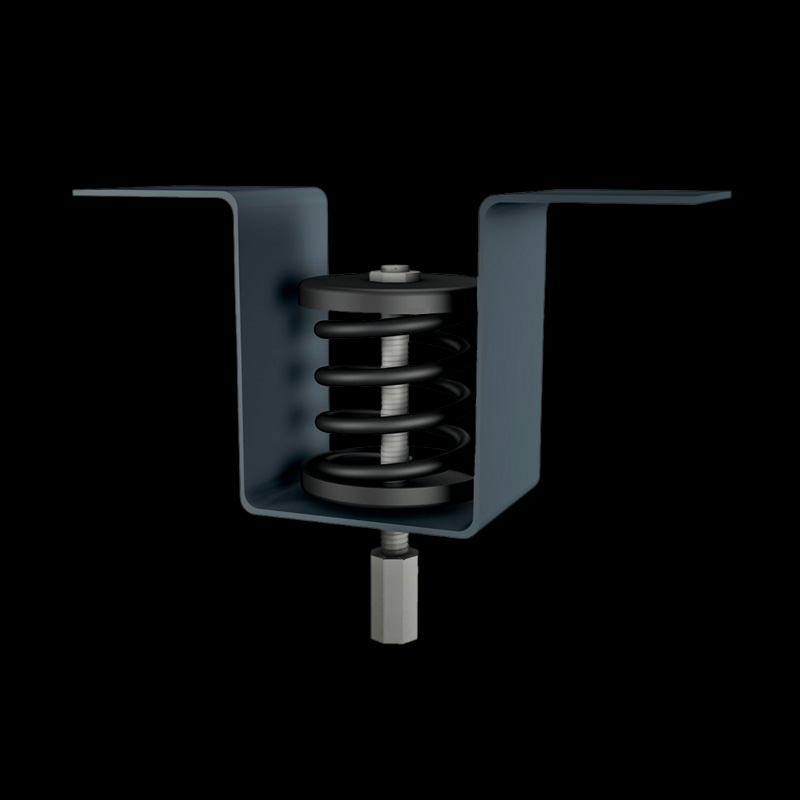

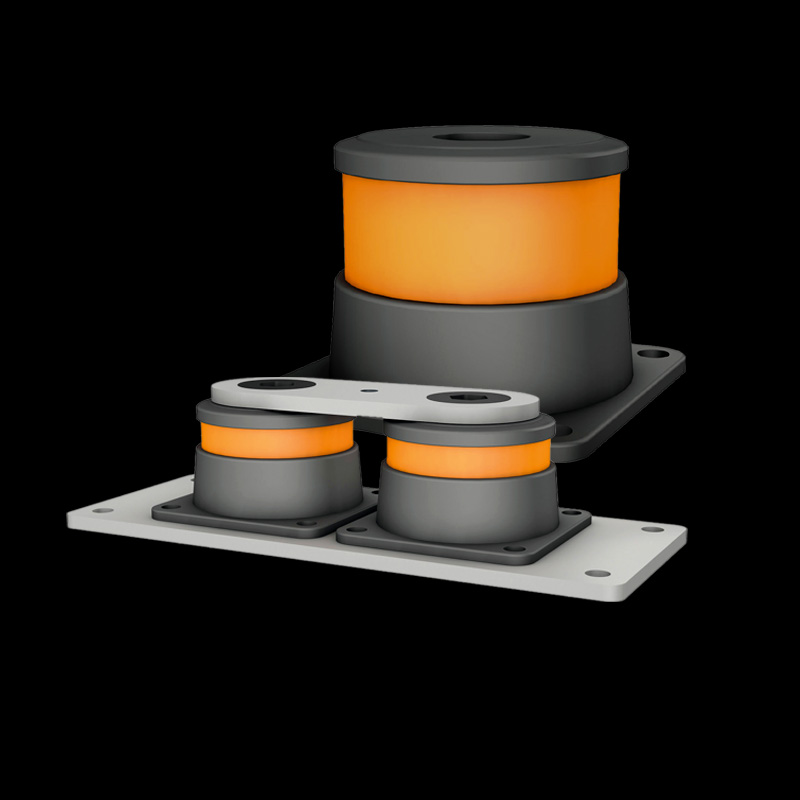

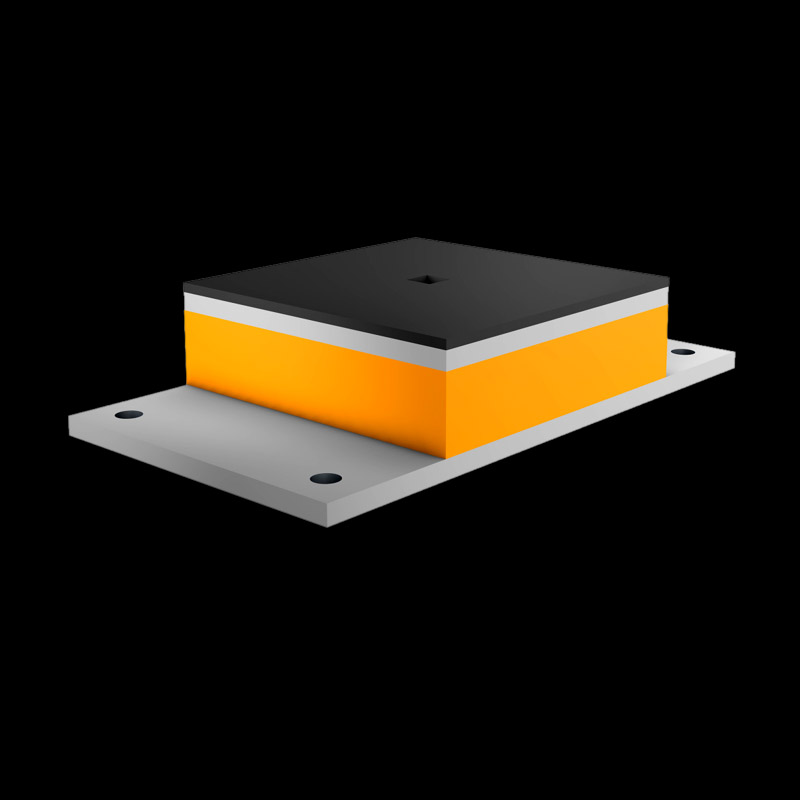

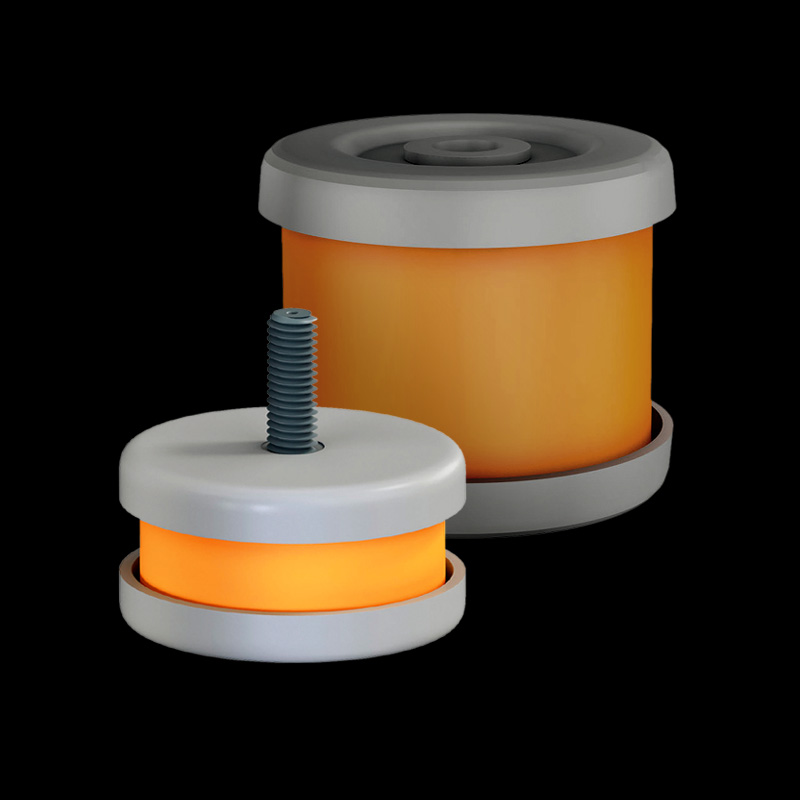

Polyurethane (Sylomer, Sylodyn, Sylodamp and Isotop) is often considered a better vibration damper than rubber in most applications due to its unique combination of mechanical properties. Shown below are some of the key reasons why the physical properties found in Polyurethane enable it to outperform rubber as a vibration damper.

Resources Features and Benefits Anti-Vibration Importance HVAC Anti-Vibration Polyurethane Vibration Dampeners

key reasons why Polyurethane vibration dampeners will outperform rubber

Higher Load-Bearing Capacity

Polyurethane has a higher load-bearing capacity compared to rubber, which allows it to support heavier machinery or equipment without significant deformation. This makes it ideal for applications where high loads and stress are involved.

Rubber, on the other hand, can deform more easily under heavy loads, leading to reduced vibration isolation effective ness over time.

Durability and Wear Resistance

Polyurethane is known for its exceptional durability and resistance to wear, abrasion, and tearing. It can withstand harsh conditions, chemicals, and oils, making it ideal for demanding environments like industrial settings.

Rubber is generally less resistant to wear and can degrade faster, especially when exposed to oils, chemicals, or UV radiation, leading to a shorter lifespan in certain conditions.

Wider Range of Hardness

Polyurethane can be formulated to exhibit a wide range of hardness levels, from very soft to very rigid, which allows engineers to fine-tune its vibration damping properties for specific applications. This flexibility makes it versatile for both soft damping (low-frequency vibrations) and hard damping (high-frequency vibrations).

Rubber has a more limited range of hardness options, which can constrain its performance in certain vibration isolation tasks.

Temperature Resistance

Polyurethane generally performs better across a wider temperature range. It maintains its mechanical properties in both low and high-temperature conditions without significant loss of damping capacity.

Rubber is more sensitive to temperature extremes. It can harden and become brittle in cold conditions or soften and degrade in higher temperatures, which reduces its effectiveness as a vibration damper over time.

Customizability and Tunability

Polyurethane materials can be customized for specific vibration frequencies and damping characteristics, making it easier to design precise solutions for various industrial and commercial applications.

Rubber is less customizable in terms of its frequency response and damping behaviour, often providing a more generalized solution that may not be as finely tuned to particular needs.

Longer Service Life

Polyurethane generally has a longer service life than rubber in vibration damping applications because it resists fatigue, environmental wear, and degradation over time.

Rubber can crack, tear, or lose its elastic properties, especially when exposed to prolonged stress, heat, or chemicals, leading to faster deterioration.

Energy Absorption and Rebound

Polyurethane has excellent energy absorption and rebound properties. It can absorb shocks and dissipate energy more effectively while also quickly returning to its original shape after deformation. This helps maintain consistent performance over time.

Rubber tends to have higher hysteresis losses, meaning it absorbs energy but does not return it as efficiently, which can result in heat build-up and less consistent damping performance, particularly under repeated or cyclic loads.

Resistance to Environmental Factors

Polyurethane is more resistant to environmental factors like oils, fuels, solvents, ozone, and UV light, which can degrade rubber.

Rubber is more prone to degradation when exposed to these elements, especially in industrial or outdoor applications.

Resilience and Elastic Modulus

Polyurethane has a higher resilience, which means it can withstand repeated stretching and compressions without permanent deformation. It has a greater elastic modulus, meaning it can store and release more energy during the damping process.

Rubber may not offer the same level of resilience, leading to potential fatigue and material breakdown under cyclic loads.

Further reading

Isotop Features and Benefits

Isotop products from Getzner Werkstoffe are specifically designed to stop or significantly reduce machine vibration, making them ideal for a wide range of industrial applications.

Anti-vibration importance

Reducing machine vibration is crucial for a variety of reasons, including enhancing equipment performance, longevity, safety, and operational efficiency.

HVAC Anti-Vibration

HVAC systems are essential for maintaining indoor comfort, but they can also create vibration problems that negatively affect both the system itself and the surrounding environment.

In Summary: Polyurethane vibration dampers are specialized components used to reduce vibrations and shock in various applications, including automotive, industrial machinery, and construction. These dampers are made from polyurethane, a versatile polymer known for its durability and elasticity. They work by absorbing energy from vibrations, thereby minimizing their transmission to other structures or components. This helps to enhance the performance and longevity of machinery and improve comfort in vehicles.